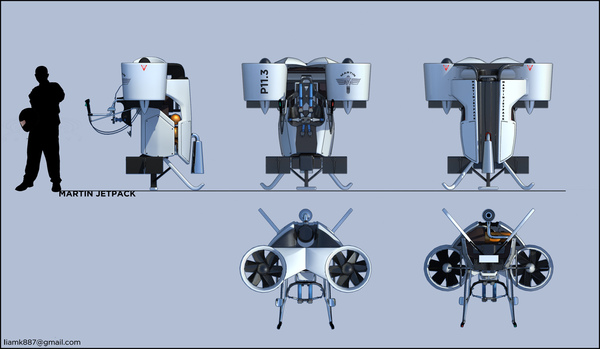

Composite Airframe

Composite Airframe:

The Martin Jetpack composite airframe has been developed using the latest composite technologies. The use of composite materials is essential to meet the unique demands of the Martin Jetpack.

Each component or assembly has been engineered to be lightweight, strong and rigid. The composite structures, designed and developed in conjunction with Dynamic Composites account for less than 30% of dry machine weight.

Key manufacturing processes:

★ Prepreg

★ Resin infusion (V.I.P)

★ Vacuum bagging

★ Rapid manufacture tooling

Current Composite Airframe Specifications:

Ducts - Carbon fibre, aramid fibre, honeycomb core, epoxy resin

Fans - Epoxy prepreg carbon fibre, aramid fibre, foam core

Main Beam - High modulus carbon fibre, foam core

Spine - Epoxy prepreg carbon fibre

Fuel tank - Carbon fibre, Kevlar, fuel resistant epoxy resin

Undercarriage - Carbon fibre, epoxy resin, aluminium alloy

Engine heads - Carbon fibre, high temp flame resistant vinylester resin

Airboxes - Carbon fibre, epoxy resin